UV Casting & Laminating Films

Techspan, well recognised for their extensive range of hot and cold stamping foil has recently added UV Casting film and laminating film to their offering to the printing industry.

“Techspan is very dedicated to our customers and when people come to us and ask if we can source or supply something we go looking to see if it is viable. As the manufacturer of our cold foil also produces both of these products the solution was a simple exercise” says Warren Hadler of Techspan Group

Laminating Film is applied from a roll usually to sheet stock and can often be found on packaging to give a gloss or matted down effect and quality feel to the finished item, it also provides a durable surface which has wear resistant properties to protect the printing and stock from abrasion and contaminates.

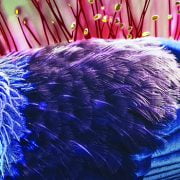

Like stamping foil, laminating film adds value and comes in a variety of holographic patterns. A look of quality and eye catching embellishments are very important when competing for attention and needing to standout in a retail environment.

Available in thicknesses of 12,15,23,38 and 50 microns with 12 – 15 generally used for carton work.

Casting film is applied to a UV coating during the printing process to treat the surface at press speed and in register leaving a holographic effect much like a transparent holographic foil (also supplied by Techspan) does . The image is in the casting film which actually micro embosses the surface of the varnish when, holds it until it is UV cured and then peeled away. As there is no transfer from the casting film to the substrate, careful rewinding of the film means it can be used over and over again achieving several passes out of a single roll.

Casting film can be used for complete coverage or as a spot embellishment and does not require any additional skills from the press operator.

Need further information?

Phone: +64 9 827 6567 ext. 709

Phone: +64 9 827 6567 ext. 709Mobile: +64 275 701 709

Email: click here to email WarrenHaving worked in the print finishing industry for most of his life Warren Hadler has seen a lot of change and progress, and although he has not moved around much himself he remains right up to speed with what the market wants from suppliers and needs from the products they supply. As many people in the industry will know, Warren has a passion for what he does, he loves foil and what it can do for a product as an embellishment.